Our factory is a specialized manufacturer in the audio industry, operating from a facility spanning over 6,000 square meters,we focus on providing ODM and OEM services for a wide range of audio products. Equipped with advanced automated production lines and a highly flexible manufacturing setup, our modern production base efficiently accommodates diverse batch sizes and product types. The integration of an MES intelligent production system allows real-time monitoring, precise process scheduling, and optimized resource management—significantly enhancing both production efficiency and product consistency.

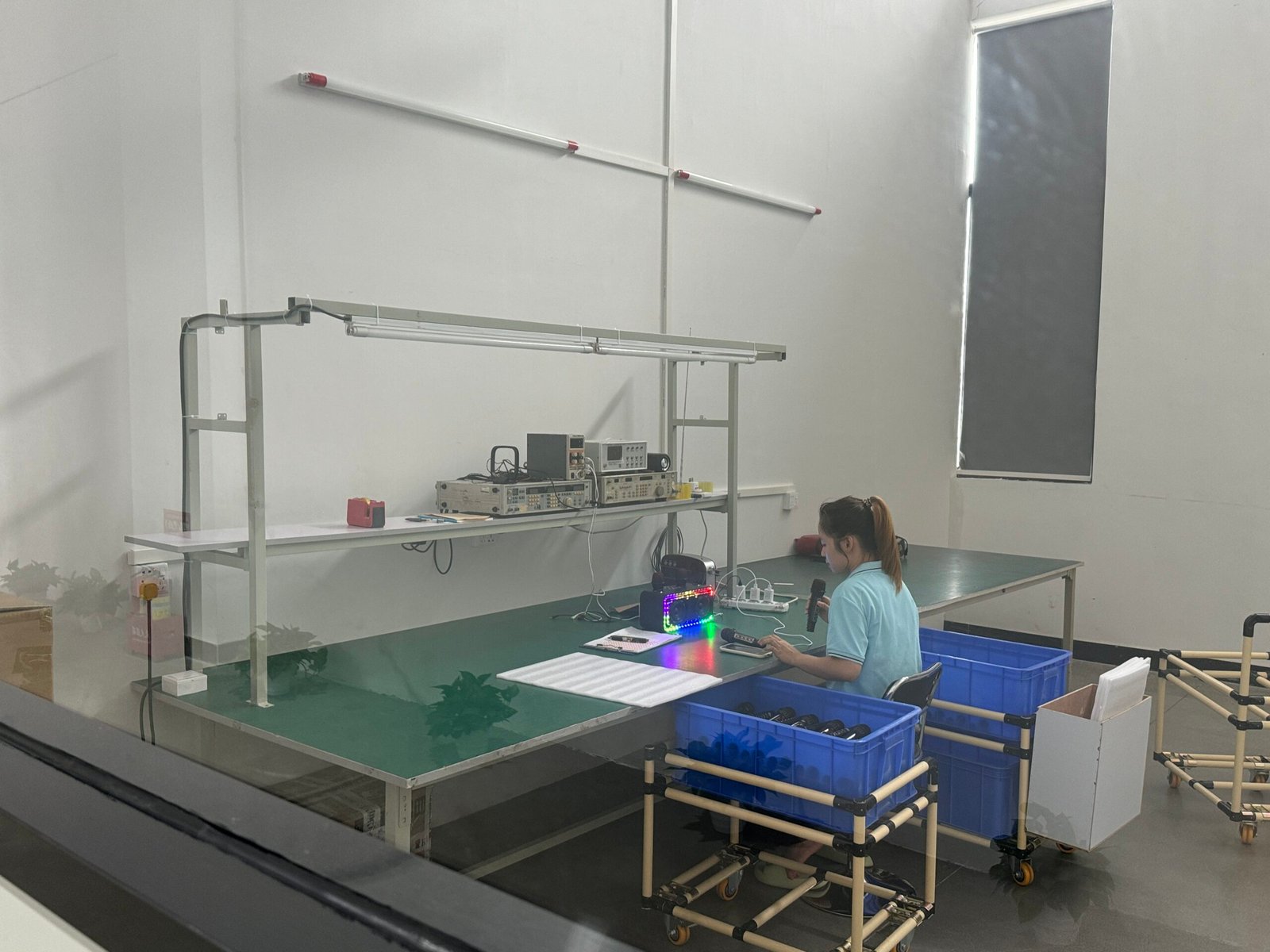

Quality control is the core of our production management. The company has obtained ISO quality management system certification and BSCI certification, which not only ensures the stability of product quality but also demonstrates our commitment to ethical production and social responsibility—an essential “passport” for cooperating with major retailers and purchasers. We have established a strict quality control system covering the entire production process: from the incoming inspection of raw materials such as speaker cones and voice coils, to in-process testing of circuit boards and assembly processes, and finally to the final acoustic performance testing in the professional anechoic chamber. Every product must pass multiple strict tests before leaving the factory to ensure high quality and reliability.

With over 200 employees, the company has built a professional team with strong comprehensive strength. Our innovative R&D team has an average industry experience exceeding 10 years, and has established in-depth cooperation with universities and industry technology leaders. We have independently developed core technologies such as intelligent power management and ETQ room acoustic test correction system, and have obtained multiple invention patents. The experienced quality control team implements full-process monitoring with professional testing equipment and strict testing standards. Our product portfolio is rich and diverse, covering Bluetooth speaker, Clock speaker, Karaoke speaker, Soundbar, TWS earbud, Headphone and other audio products, and we can also provide customized audio solutions according to customer needs, building a diversified and comprehensive product and service system.

Total Area

Assembly Line

Monthly Production Capacity

Quality Inspection

On our synchronized production line,each unit must then pass rigorous initial electrical checks and endure hours of controlled burn-in testing to stabilize components and weed out early failures. Finally, every speaker is auditioned by our seasoned audio engineers in a dedicated listening environment and verified with objective instrument measurements, ensuring its performance meets our target for a balanced, detailed, and moving sonic character. It is through this unwavering commitment to craftsmanship and strict quality control at every stage that we deliver the pure, accurate, and perfect sound experience to you.

IQC Inspection

Laboratory

Aging test room

Inspection room

Our commitment to speaker quality begins with rigorous incoming material inspections, where every core component undergoes precise screening. This is followed by in-process testing and scientific validation in our professional laboratory, utilizing anechoic chamber data analysis and environmental reliability tests to ensure performance and durability. Each finished product must then endure hours of dynamic burn-in treatment to stabilize its performance, before finally undergoing comprehensive inspection of appearance, functionality, and subjective listening evaluation. This seamlessly integrated, precision-driven system forms the solid foundation upon which we deliver consistent quality and pure sound reproduction.

It is meticulously zoned for raw materials, work-in-progress, and finished goods, all managed under a lean inventory system with real-time tracking to guarantee accuracy and efficiency. By adhering to strict FIFO principles, standardized procedures, and a controlled environment, we ensure every component and finished speaker is protected from receiving to dispatch.

Dust-free Workshop

Material Warehouse

Finished Product Warehouse

Mold Manufacturing Workshop

Automated Production Line

Feel free to fill out our contact form below and our support team will

get back to you within 24 hours.

7th Floor, Block A, Huizhi R&D Center, Xixiang Street, Baoan District, Shenzhen, Guangdong Province

Johnson@keno-tech.com

+86 0755-23225586